Looking to rapid change in fashion trends and the desire for functional garments, call for innovative developments in the field of textile machinery and specialty yarns. In the recent scenario of globalization, particularly in textile industry not only productivity is the factor of vital importance but also quality at all stages of manufacture from raw material to end product. For success of commercial spinning necessitates pre – test runs of small samples in order to assess the twist, draft, yarn tension, spindle speed etc., that are needed to produce yarns of the required quality.

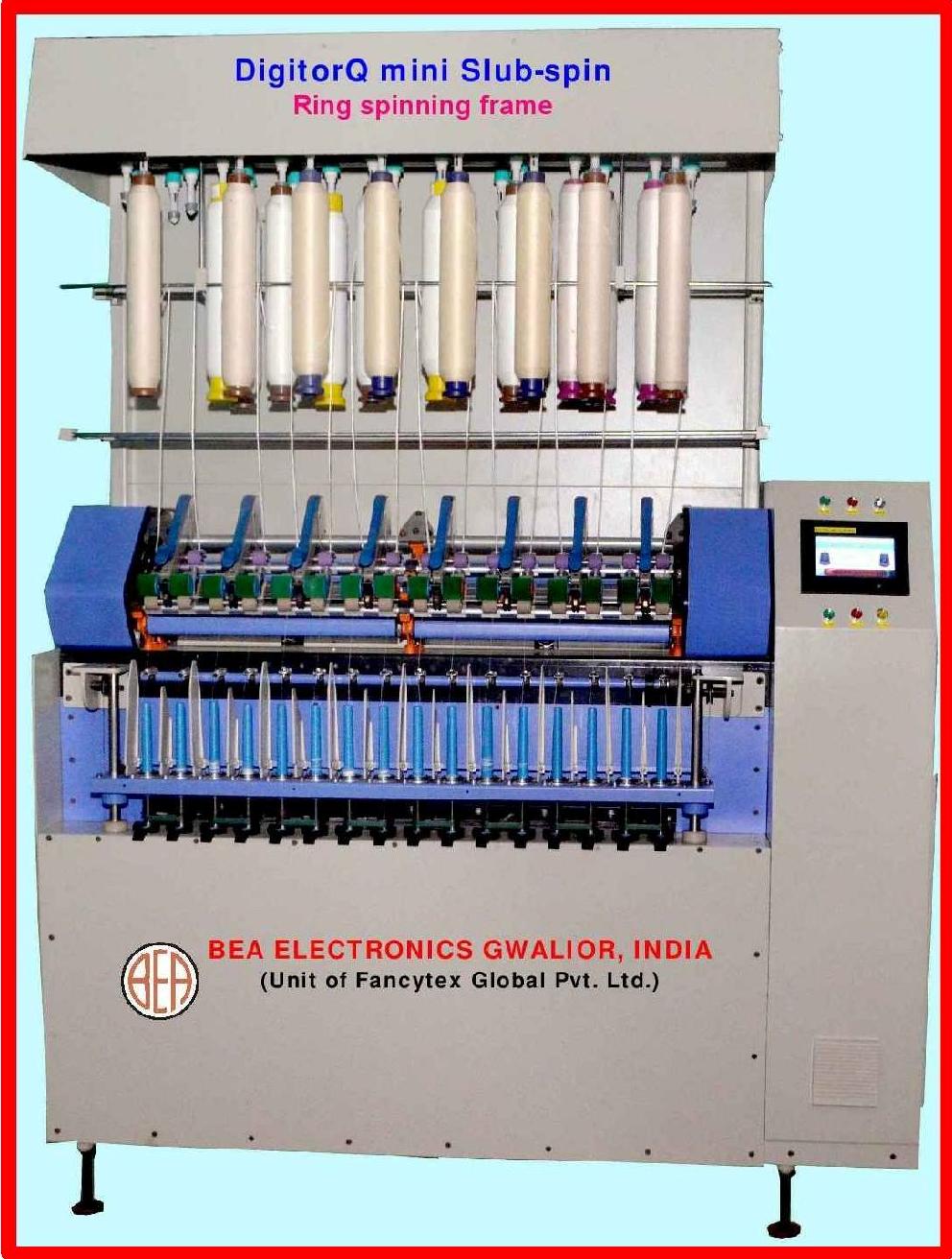

The end-product has a good effect due to pre-test run, facilitates trying various combinations of manufacturing techniques and saves precious raw material and manufacturing time. Also it does not require the use of a large sample size which is normally required to do the same experimentation in the conventional machineries. Due to these new trends the R&D section of the BEA ELECTRONICS has developed “DigitorQ mini Slub-spin” Ring Spinning Frame.

The following are the main objectives of “DigitorQ mini Slub-spin” Ring Spinning Frame:

- a) To help the mills to conduct test runs.

- b) To incorporate yarn feeding facilities and control to facilitate trial fancy yarn production.

- c) To train students of the Textile Technology and trainees in yarn production shop.

In any continuous manufacturing process operated on a large scale, it is needed for testing the material for its suitability and unless adequate tests are made, there remains an element of uncertainty with the added possibility of wasted time, effort and materials. Often, a true assessment of the material can be obtained only by observing its behavior during processing or by tests on the finished products. The comprehensive testing involves at least some of the main stock to the whole manufacturing process. Since it is impossible to treat very small samples on a full scale spinning plant, special testing equipments and techniques are required.

Pilot plant scale production machines are the only way in which information on the production process can be obtained without major wastage of material or interference with production. Improvement in the speed and accuracy of yarn testing has contributed to the interest in miniature spinning system. The miniature spinning system consists of mini Slub-spin. “DigitorQ mini Slub-spin” is the first in the series of machinery development for the miniature spinning system. The work related to development of other miniature machines has been initiated. There was a good response from the member mills for such a miniature spinning system.

With the use of above technique, electronic controlled 100% servomotor operated miniature ring spinning frame “DigitorQ mini Slub-spin” has been designed and developed using the sophisticated state-of-the-art control systems. This spinning frame is a sixteen – spindle machine with single phase 220V AC supply and occupies as little space as possible.

“DigitorQ mini Slub-spin” test ring spinning frame is a universal machine with many innovative features which make the machine an ideal choice for experimental yarn production. With this mini spinning frame, mills will be able to maximize process parameters such as

- twist

- back draft , total draft

- spindle speed

- yarn tension

- lift

- roller settings etc

Also, this digitally controlled miniature frame offers maximum flexibility for changing the slub yarn parameter interval, slub thickness, slub length and random slub yarn. A range of fancy yarns like slub yarn can be produced using a specially developed software program provided along with the machine.

The salient features of the Motion controlled “DigitorQ mini Slub-spin” Ring Spinning Frame are outlined below:

Drafting rollers - front, middle and back with individual servomotors with drives for step-less variation of speed without affecting the speeds of other rollers. The back draft and total draft can be varied without any change of gears or pulleys.

The lappet in the “DigitorQ mini Slub-spin” is fixed.

AC servomotor for the spindles drive for varying the spindle speed up to 20000 rpm.

Motion controlled system for data acquisition and analysis, supervisory functions and complete machine control.

A unique purpose electronic circuit to perform different functions such as independent motor control, speed variation, smooth start etc. This required a manual method of determining correct setting in different types of fibres.

Isolation is used to prevent system from spikes.

Individual AC servomotor for acceleration, deceleration, starting and stopping without any mechanical clutches or brakes.

Provision for easy variation of drafting parameters by a digitally controlled program to produce the desired fancy effect with specific slub thickness, length and interval of the slub in the yarn.

Enhanced yarn quality with appreciable reduction in hairiness & significant increase in yarn strength with enhanced yarn appearance.

Ergonomically designed for user friendliness.

Less yarn breakage in winding, knitting & warping.

Improved fabric behaviors.

Improved efficiency.

Better performance.

Better working atmosphere.

“DigitorQ mini Slub-spin” is an ideal spinning tester with maximum flexibility for developmental studies. There are many applications for this “DigitorQ mini Slub-spin” small scale spinning technique. Some of these are:

Useful to textile mills for optimization of spinning parameters. New yarn development and spinning different fibre samples.

Provides immense scope to produce different types of fancy yarns and specialty yarns.

Machinery manufacturers can utilize “DigitorQ mini Slub-spin” for optimizing spinning geometry. Testing of sub assemblies and new components and to determine best possible conditions for automation studies.

Useful to accessories manufacturers for optimizing and testing their own products in addition to new developments.

Can be used for preparing calibration yarn as per the specific requirement of various sectors.

Ideal for Research and Development Institutes for carrying out technological research and material testing under various conditions and

For Universities, Educational Institutions and Training Centers for textile training in Spinning and experimental purposes.

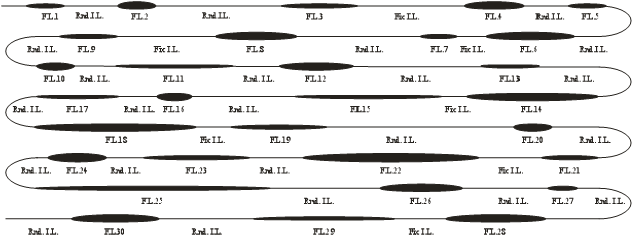

“DigitorQ mini Slub-spin” can produce Slub Yarn by SLUB-O-GENERATOR both of patterning or anti-patterning type with slubs of any programmable length and dia. It can produce different counts effect in the same yarn. Slub yarn of any count above 8’s count can be produced by this Machine.

Appearance of Slub:-

Ex. - Slub Effect Pattern –

(Different F.L. with Random I.L. & Fix I.L.) Slubs of Two thicknesses

| A. | Power supply | 220V AC, 1- phase, 50Hz |

|---|---|---|

| B. | Dimension | (L)1810mm x (W) 680mm x (H)2420mm |

| C. | No. of Spindles | 16 |

| D. | Material | Synthetic or Cotton according to customer |

| E. | Spindle speed | 5000 to 20,000 RPM |

| F. | Drafting | PK-225 |

| G. | Counts | From Ne10 up to Ne80 |

| H. | Spindle gauge | 70 mm |

| I. | Spindle size | 7” – 1/40 Tapper |

| J. | Ring Diameter | 38 mm |

| K. | Lift | 170 mm |

| L. | T.P.I. | 5.00 to 60.00 |

| M. | Draft | Up to 60 |

| N. | Flute Roller | Front Roller – 27mm, Middle Roller –27mm, Back Roller – 27mm |

| O. | Cradle | Short Cradle |

| P. | Drive | Servo drives 5# |

| Q. | Touch Control screen | To display Spindle Speed, Front Roll Speed, Running Slub Length, Interval Length & Slub dia., Total Yarn Length |

| R. | Slub Length | 50 to 30000 mm |

| S. | Interval Length | 50 to 30000 mm |

| T. | Slub Diameter | 1.2 to 9.99 times of normal yarn |

| U. | Negative Slub | 0.5 to 0.8 times of normal yarn |

| V. | Total weight | 450 Kgs. |

Types of Fancy Effects –

1. Normal Yarn

2. One Colour Ground Slub (OCGS)

3. Two Colour Injected Slub (TCIS)

4. Multi Count Multi Twist (MCMT)

5. Ground Slub and Injected Slub both in the same yarn (TIO)

6. Two colour Injected Slub with Multi Count Multi Twist (TCMT)

7. Negative Slub